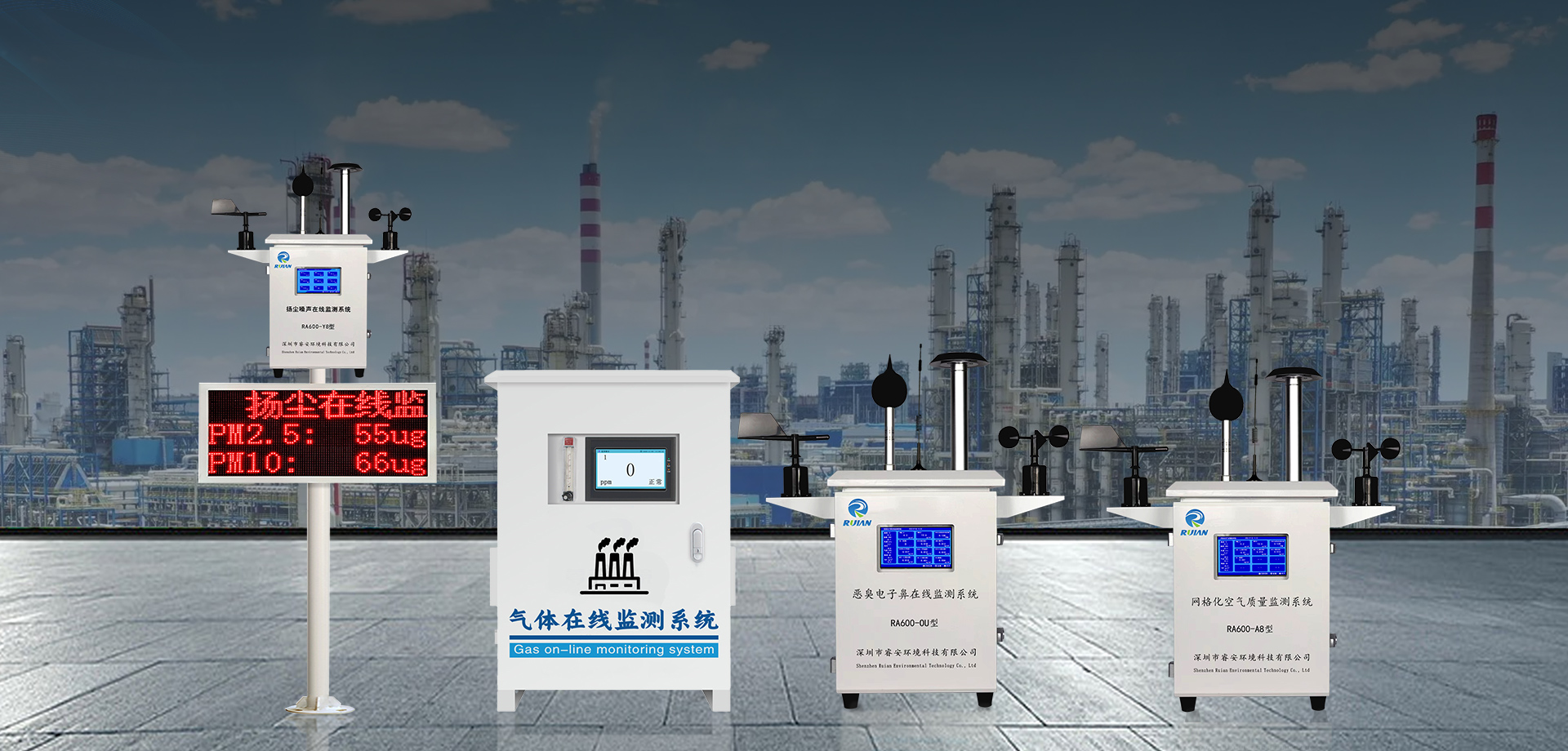

One-stop environmental monitoring expert

Select the region/language

Select the region/language

Select the region/language

company introduction /Company Profile

Shenzhen Rui 'an Environmental Technology Co., Ltd. was founded in 2013, is a collection of ecological environment monitoring and industrial safety monitoring system service provider. The company focuses on the research and development and manufacturing of gas detector, particulate dust online equipment, gridded air quality monitoring station, odor electronic nose and other ring filling analysis instruments, as well as providing complete industrial safety and environmental monitoring system solutions; The company is always stuck in the environment and security scene, from equipment, platform to operation and maintenance, providing online and offline integrated design, construction and operation services, committed to improving the urban environment and public safety service level, guide the development and upgrading of Zhiyue city. Ke 'an ring adhering to the "protect human security, let the earth to reproduce the blue sky and white clouds!" We vigorously implement the self-owned brand strategy, increase the investment in R&D and innovation, enhance the competitiveness of products, explore and improve the added value of products and services, constantly strengthen the ability of the agon market, strengthen the humanistic beauty and social responsibility, which drive the company to sustainable, stable and healthy development.

Data platform /

Intelligent industry /Industria lsafety

-

Gas alarm detector

Gas alarm detector

-

Gas control alarm

Gas control alarm

-

Dust particle monitorin...

Dust particle monitorin...

-

Tube gallery tunnel mon...

Tube gallery tunnel mon...

-

Gridded air quality mon...

Gridded air quality mon...

-

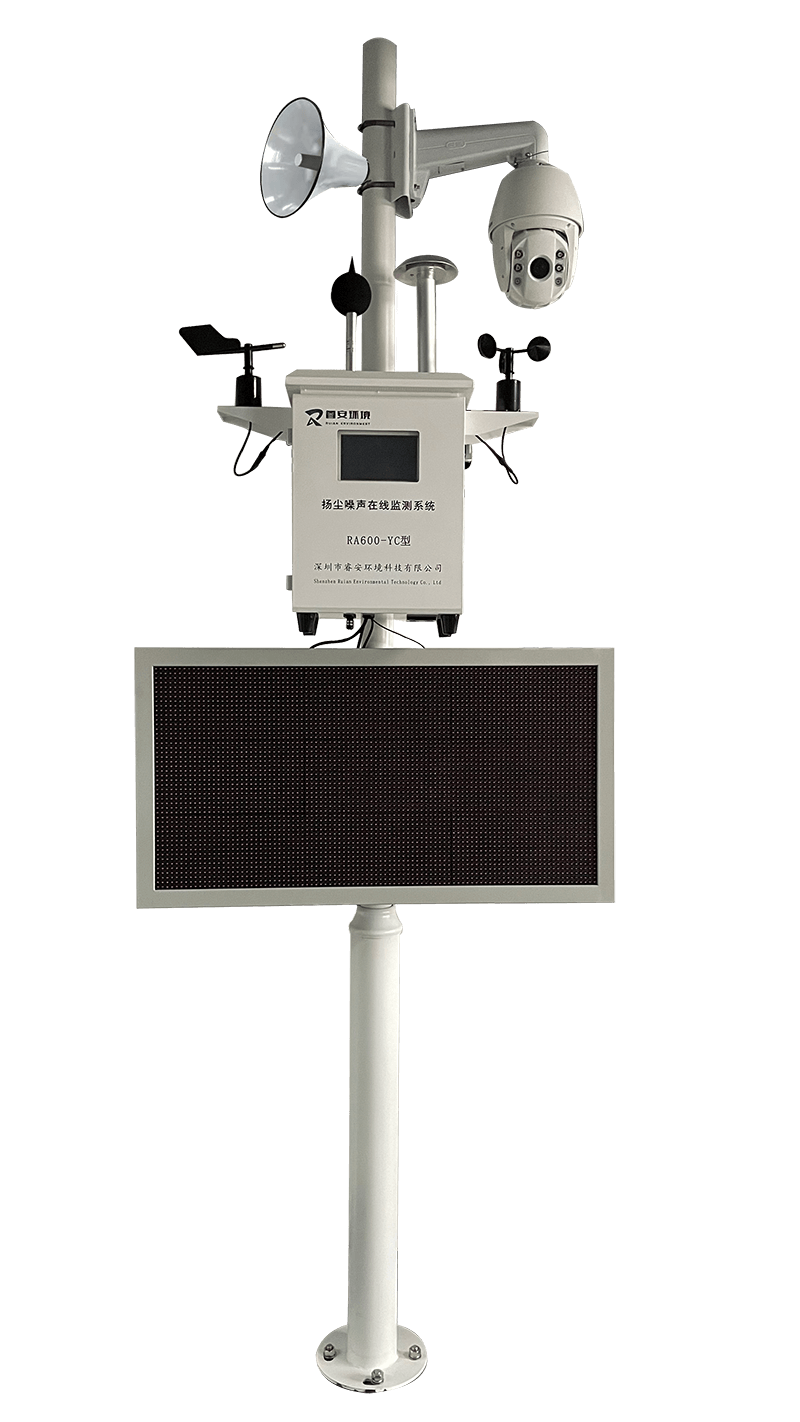

Dust on-line monitoring...

Dust on-line monitoring...

-

Toxic gas monitoring

Toxic gas monitoring

-

Odor monitoring

Odor monitoring

-

VOC on-line monitorin...

VOC on-line monitorin...

-

Flue gas detector

Flue gas detector

-

Carbon emission monitor...

Carbon emission monitor...

-

Pot nitrogen oxide moni...

Pot nitrogen oxide moni...

-

Intelligent monitoring

Intelligent monitoring

-

More products+

More products+

Environmental protection /Environmental protection

company introduction

company introduction

Data platform

Data platform

Intelligent industry

Intelligent industry

Environmental protection

Environmental protection

Application industry

Environmental protection

With the continuous increase of national environmental control, the amount of gas detection instruments in the field of environmental protection is also increasing year by year, more and more applications in boiler flue gas detection, atmospheric quality detection and other aspects, the amount of gas sensors in the field of environmental protection is increasing year by year. In the field of environmental protection, toxic gas sensors are mainly used for the detection of flue gas, tail gas, waste gas and other environmental pollution gases. Environmental gas monitoring involves a wider range of aspects, from environmental atmospheric monitoring to industrial gas emission inspection, gas detection instruments are used.

Search more

Metallurgical industry

In iron and steel, aluminum smelting industry is widely used in carbon monoxide, sulfur dioxide, hydrogen sulfide, nitrogen oxide and other gas sensors, mainly to monitor fuel combustion status, improve fuel utilization, energy saving and consumption reduction; Monitor the condition of exhaust gas, reduce pollution; At the same time, it also detects gas leakage in industrial places to ensure production safety and prevent occupational diseases.

Search more

Mining industry

The coal industry, one of the key energy industries that support the rapid development of Chinese economy, has a larger number of gas sensor equipment. Our country is a big coal mine safety instrument equipment country, and it is also one of the important producing countries of coal mine safety instrument. At present, there are millions of gas sensors in key coal mines, but the safety problem is still serious, and the number of casualties and property losses are unprecedented. Therefore, the state pays more attention to the safety requirements of coal mines. Gas detection equipment, which not only improves the level of coal mine gas detection, but also pulls the upgrade of gas detection industry.

Search more

Chemical industry

In the industrial route, whether it is coking industry, coal gasification and synthetic ammonia, coal-based methanol, coal-to-synthetic oil, coal-to-chemical co-production, there is a wide range of gas detection products, especially for sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine gas, ammonia gas and other gas sensors are in great demand.

Search more

Gas industry

A large number of natural gas field development and pipeline construction will greatly increase the demand for gas detection equipment, high-performance infrared gas detection instruments and meters have been a rare opportunity for development. In the process of gas mining, processing, transportation and use, the demand for combustible gas testing instruments will reach hundreds of thousands of sets.

Search more

Petroleum and petrochemical

In petroleum production, gas detector is also needed for the detection of flammable gas leakage and the monitoring of hydrogen, oxygen and other environmental gases. It is estimated that about 40 gas testing instruments (sets) are required for every 10,000 tons of refined oil production, including 20 sets of combustible gas. Based on the current annual output of 220 million tons of refined oil, the annual demand for gas testing instruments is about 880,000 sets (sets). Among them, combustible gas testing equipment is about 440,000 units (sets), toxic gas testing equipment is about 220,000 units (sets), and other organic steam and gas analysis equipment is about 220,000 units (sets). There is also a great demand for gas detectors for detecting combustible gas, carbon monoxide, sulfur dioxide, hydrogen sulfide and organic vapors such as benzene, aldehydes and keones in all kinds of oil and gas stations, which are mainly used for safety protection to prevent poisoning and explosion accidents. On average, 7.2 sets of gas detection instruments are required for each oil and gas station.

Search more

development history

2022

-

Born -2013Born in 2013 (Shenzhen Rui 'an was established in Shenzhen, the national Special Economic Zone, committed to the research and development and manufacturing of instruments);2013

Born -2013Born in 2013 (Shenzhen Rui 'an was established in Shenzhen, the national Special Economic Zone, committed to the research and development and manufacturing of instruments);2013 -

Growth -2015Growth -2015 (the company entered the period of rapid business growth after two years of development);2015

Growth -2015Growth -2015 (the company entered the period of rapid business growth after two years of development);2015 -

Experience -2017Experience -2017 (the company laid brand foundation in the pipeline corridor industry, petroleum and petrochemical industry);2017

Experience -2017Experience -2017 (the company laid brand foundation in the pipeline corridor industry, petroleum and petrochemical industry);2017 -

Transformation -- 2018Transformation -2018 (the company has played a huge role in monitoring volatile organic compounds emissions in 2+26 cities such as Beijing, Tianjin and Hebei, and successfully transformed the environmental monitoring industry in the same year);2018

Transformation -- 2018Transformation -2018 (the company has played a huge role in monitoring volatile organic compounds emissions in 2+26 cities such as Beijing, Tianjin and Hebei, and successfully transformed the environmental monitoring industry in the same year);2018 -

Anchor -2019Anchor-2019 (The company carries out multiple optimization for the product line to establish the development direction of wisdom safety and wisdom environmental protection)2019

Anchor -2019Anchor-2019 (The company carries out multiple optimization for the product line to establish the development direction of wisdom safety and wisdom environmental protection)2019 -

Expansion -2020Expansion -2020 (the company diversifies its environmental monitoring business, and sets up a research and development intelligent manufacturing center in Suzhou, covering the whole Yangtze River Delta industrial Economic belt);2020

Expansion -2020Expansion -2020 (the company diversifies its environmental monitoring business, and sets up a research and development intelligent manufacturing center in Suzhou, covering the whole Yangtze River Delta industrial Economic belt);2020 -

Perfect -2022Perfect -2022 (the company improves various qualifications, obtains a number of patent works, and actively applies for national high-tech and specialized special new enterprises, keeping up with the pace of national development strategy);2022

Perfect -2022Perfect -2022 (the company improves various qualifications, obtains a number of patent works, and actively applies for national high-tech and specialized special new enterprises, keeping up with the pace of national development strategy);2022 -

Leap Forward -2023Leap Forward -2023 (Stay true to your original aspiration, forge ahead, continue to grow, and achieve your mission)2023

Leap Forward -2023Leap Forward -2023 (Stay true to your original aspiration, forge ahead, continue to grow, and achieve your mission)2023